Mailer Boxes

Create a memorable unboxing experience with our Mailer Boxes.

Custom mailer boxes are used to deliver almost anything including ecommerce orders, subscription boxes, and promotional kits for every industry, from beauty to food & wine to clothing.

Why is UPrinting the best choice in custom boxes?

Our printing services let you design your own mailers—customize every detail, from choosing a custom size to executing the most intricate design. We offer:- Digital production

- Sustainably sourced materials

- Easy design tool

- Instant pricing

- Flexible production (choose rush/standard)

Fold and Flap - it’s as easy as that!

Our Roll End Tuck Front box is designed for easy and quick assembly with extra protection. It comes scored to indicate which lines are for folding. Save time (and tape!) so you can get your products out the door and in front of your customers.How to Assemble Your Mailer Box

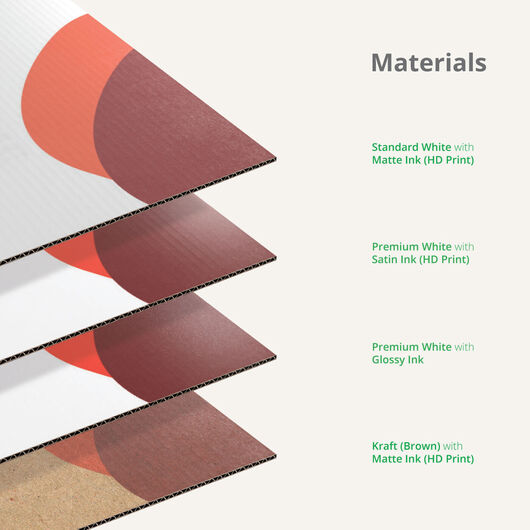

Sustainable & Sturdy Material Options

3 Paper/Stock Options

Standard White with Matte Ink (HD Print)

- Popular, economical option

- Made of sturdy, sustainable material

- Uncoated finish

Premium White with Satin Ink (HD Print)

- Smooth surface with a feel

- Clay-coated for a whiter brighter finish

- Best for luxury brands, gift boxes and promotional kits

Kraft (Brown) with Matte Ink (HD Print)

Material thickness

We automatically select a material thickness that works best for your box dimensions. If you require a specific thickness, please contact us.

- .

- .

Sustainable & Durable

Our custom mailer boxes are made of sustainable, recyclable, and sturdy corrugated cardboard. No extra packaging needed to send your corrugated mailers.

Custom Mailer Box Sizes

We produce your custom mailers in the exact size you need within the following ranges:

Take your mailers to the next level with

Custom Inserts

Our dedicated US-based packaging team will work with you throughout the process to design and order the perfect inserts for your mailers.

Custom Mailer Box FAQ

Production and delivery times vary based on your order size. Once your artwork is approved, it takes 4 -15 business days to produce your full-color boxes. Black ink mailers take 10-12 business days for production. Transit-time will be 2-5 business days from there depending on the shipping method you select at checkout. If you need the mailer boxes sooner, Rush options may be available with production times of 4 - 8 business days. Read more about our production and turnaround times.

You can order your custom boxes in three easy steps:

- Customize it - Select the perfect style, dimensions, and material at the top of this page.

- Design it - Use our intuitive online design tool to easily design your makeup boxes. You can also send us a completed design.

- Get it - That's it! We'll produce and ship your custom boxes to your door. You now get to place your product inside for a striking branded look.

Of course! We can make you a single custom box with your own design and dimensions. To order, set the quantity to “1” at the top of this page.

No, there will be no difference between the sample box and the full production run. The primary purpose of the sample box is to allow you to evaluate the material quality and print before placing a larger order. This test order also follows the same production turnaround as a regular order.

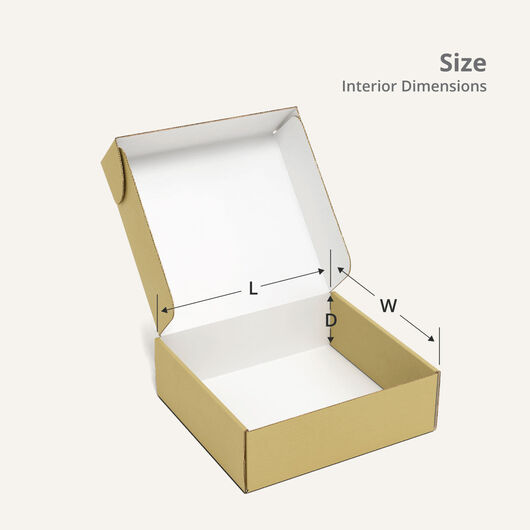

With the box open toward you, here's how to get the correct measurements for the inside of the box:

- The length is measured from the left to right side of the box.

- The width is measured from the front to the back of the box.

- The depth is measured from the top to the bottom of the box.

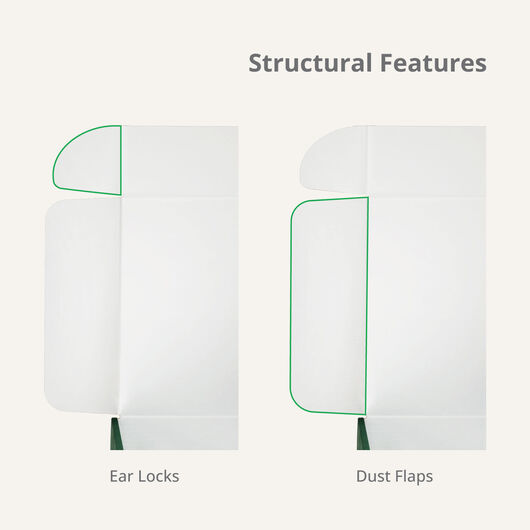

To ensure your box closes and assembles properly after printing, start by using our dieline template, which is automatically generated once your order is placed. This template outlines the exact fold lines, glue areas, and dimensions. Double-check that your artwork does not overlap glue flaps or interfere with folds. You may request a 3D proof to confirm alignment and closure. We also offer the option to order a single box so you can physically test the fit before moving forward with a larger print order.

To ensure your box assembles and closes properly after printing, start with our dieline template, which is automatically generated once your order is placed. This template provides exact fold lines, glue areas, and dimensions. Review the structural guides — bleed, cut, fold lines, and glue flaps — and confirm orientation with the box model to guarantee a proper fit and closure. Double-check that your artwork does not overlap glue flaps or interfere with folds. You may request a 3D proof to verify alignment and closure. We also offer the option to order a single box so you can physically test the fit before committing to a larger print run.

Yes, you can print your designs in full-color or black ink on the inside and outside areas of the mailer box. Printing on only one side of the box is also available, if you prefer.

We can arrange for a kraft-like texture to appear on the premium or standard white cardboard. You can contact our customer service for more information. Otherwise, white ink will appear brown if you select kraft as your corrugated cardboard color.

Achieve the closest possible color match for your mailer box with these guidelines:

- Submit your artwork in CMYK color mode. Printers use the CMYK (Cyan, Magenta, Yellow, Black) color mode when producing prints. Always make sure that you either create your design file in CMYK or convert an RGB file to CMYK before sending it to your printer.

- Review PDF proofs carefully. Digital proofs are viewed in RGB on a screen, which may appear lighter or more vibrant than the final printed box.

- Order a sample box first. You can order one (1) sample box to use as a test run. This way you can see see how the colors appear on the actual box before committing to a full production run.

- Consider the box material and finish. Different materials can affect how colors appear.

- Use ICC color profiles when creating your box design. These profiles help translate colors correctly between your screen and the printing press.

- Calibrate your monitor regularly. Screen brightness, contrast, and color settings can affect how colors appear during proofing.

- Use high-resolution images and graphics. All images should be at least 300 dpi at the final printed side. If you must use low-resolution images, avoid enlarging them to prevent pixelation or blurring.

- Submit artwork in CMYK color mode. Printers use the CMYK color mode when producing prints, and this include mailer boxes. RGB files may convert poorly to print and cause unexpected color shifts. If your file is in RGB color mode, make sure you convert it to CMYK before sending it to your printer.

- Choose the right box material and finish. Corrugated boxes have a textured surface, so prints won’t be as crisp or perfectly sharp as on smooth cardstock. Minor graininess in ink coverage is also normal for corrugated boxes. Standard White and Kraft boxes will still produce good-quality prints, but colors may appear slightly muted and less sharp due to their corrugated texture. If you wish to achieve vibrant, precise colors, we recommend using Premium White with Satin Ink (HD Print) for your mailer boxes.

- Ensure your design files are print-ready. Export them as PDF with embedded images and fonts to prevent quality loss.

- Order a sample box. Seeing a printed sample box helps you verify color, clarity, and print quality on the actual corrugated material before committing to a full print run.

.jpg)